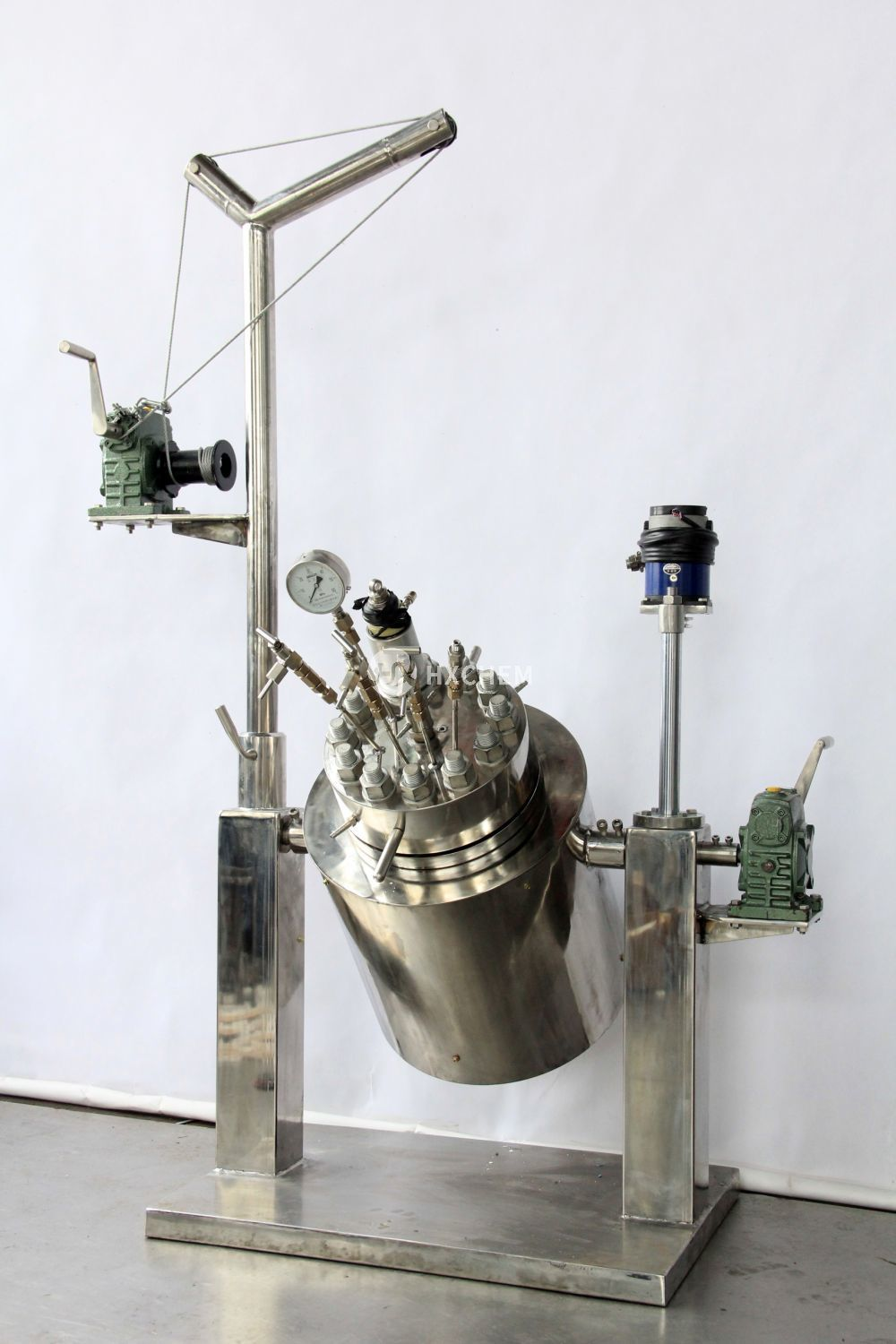

5L 200bar gulvstativ boltet lukning laboratoriereaktorer

Reaktorvolumen: 5,0 liter Maksimalt tryk: 200 bar Temperatur: 20 °C til 300 °C Materiale: Rustfrit stål 304/316 Funktioner: Karkassen kan vippes. Topdæksellåget kan hæve sig

- HXCHEM

- KINA

- 20 dage efter betaling

- 30 sæt pr. måned

Detaljer

Gulvstativ boltet lukkede laboratorietrykreaktorer

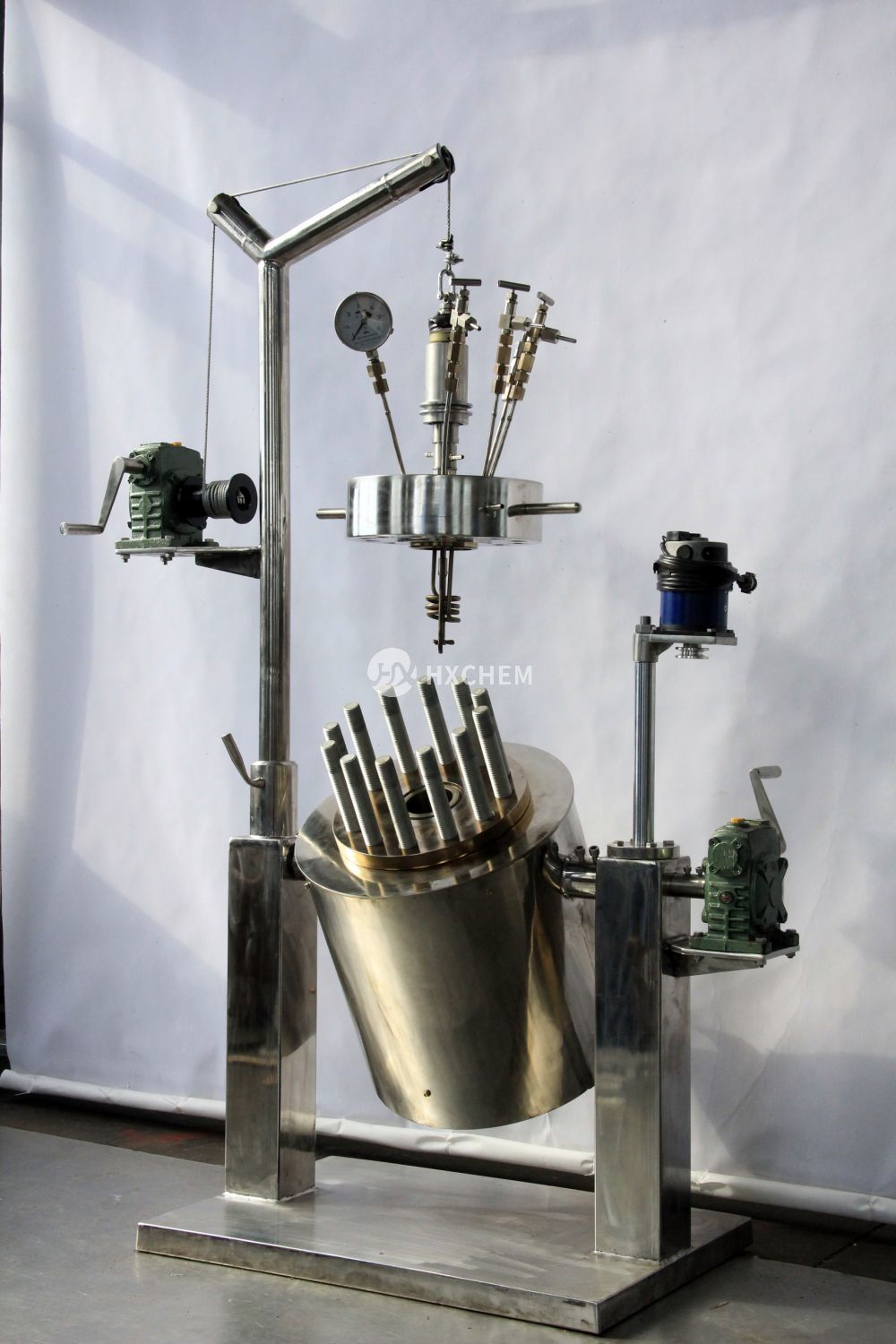

Topdæksel låg manuel løft & karrosserirotation

Reaktorvolumen:500 ml, 1 liter, 2 liter, 5 liter

Maksimalt tryk: 0-350 bar

Temperatur:20 °C til 400 °C

Materiale:Rustfrit stål 304/316, C276, Titanium osv

Funktioner:Fartøjets krop kan vippe; Topdæksellåget kan løftes og sænkes

Andre materialer, tryk og temperaturer er tilgængelige.

Funktioner

Høj temperatur og højt tryk design

Fladt låg:Løft & sænkning

Lukketype:Flangetype med boltelukning

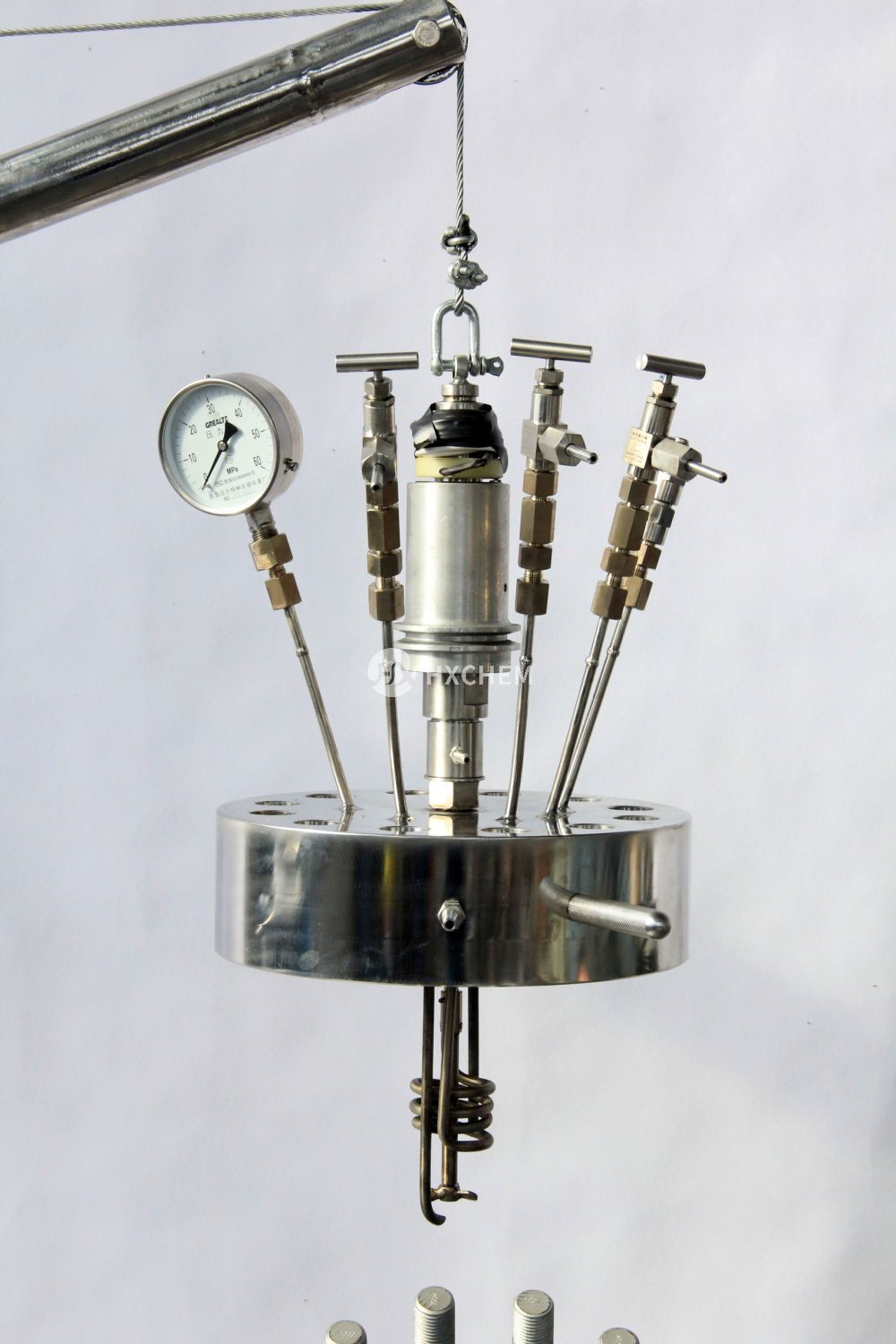

Akseltætning:Magnetisk koblingsdrev

Reaktorbeholder:Vipning

Styring:PID temperatur og omrøringshastighedskontrol.

Standard specifikationer

GSH løftereaktor standard specifikationstabel.

| model nr. | GSH-5 | GSH-10 | GSH-20 | GSH-30 | GSH-40 | GSH-50 |

| Nominel kapacitet | 5 liter | 10 liter | 20 liter | 30 liter | 40 liter | 50 liter |

| Max arbejdstryk | Standard 100bar; Max tryk op til 250bar | |||||

| Arbejdstemperatur | Standard 350°C;Op til 500°C | |||||

| Omrøringshastighed | 0-750 rpm | 0-500 rpm | ||||

| Motorkraft | 600W | 600W | 1,1 kW | 1,5 kW | 1,5 kW | 3KW |

| Varmekraft | 4kW | 9 kW | 9 kW | 12kW | 12kW | 15kW |

| Lukning | Flangebolte lukning/ Klemme lukning | |||||

Løft & sænkning | Manuelt kranløft/ Elektrisk kranløft | |||||

| Materiale | SS304, SS316 eller andre legeringer (titanium, hastelloy, inconel, nikkel osv.) | |||||

| Opvarmningsmetode | Elvarme eller Jakkevarme | |||||

| Køling | Interne spiralspoler(Valgfri) | |||||

| Opladningsmetode | Opudledning ved tryk eller udledning ved bundventil | |||||

| Løbehjul (valgfrit) | Propel, skovltype, turbine, ankertype, gasinduktion, helixtype osv. | |||||

| Kontrolpanel | Temp.display og kontrol, nøjagtighed 1℃, Visning og kontrol af omrøringshastighed Berøringsskærm programkontrol (valgfrit) | |||||

| Standard beslag | Trykmåler, termoelement, central omrørerport Væskeindtag/prøveudtagsport med nåleventil og dykrør og gasindtag med nåleventil Safety Rupture Disc: Intern køling spole (valgfrit); Solid fodring plusg(Valgfrit) | |||||

Produktdetaljer

Ansøgninger

Disse reaktorer bruges i mange grene af kemisk teknologi. Katalytisk hydrogenering med tilhørende katalysatorudvikling og -testning er bestemt en af de vigtigste anvendelser af disse reaktorer med deres fremragende trefasede blandingsdesign. Polymerudvikling er et andet stort anvendelsesområde. Derudover er karrene blevet brugt flittigt i hydrometallurgiske applikationer. Hydrogenering, Katalysator Screening / Test; Polymerisation; Styren Butadien; Alkoxylering; Destillation; Ethoxylering; Hydrokrakning; Dehydrogenering; Oxidation; Fischer trophcarboxylering; Fluid Catalytic Cracking; Biojet Brændstofproduktion; Krystallisation.

Relateret produkt